Let me tell you two short stories of two Swedish women in their thirties.

We will follow them both through their interaction with the Swedish healthcare system.

We will start with Maria.

It is Monday morning and as Maria gets dressed she discovers a lump in her left breast.

She is concerned, and with just cause.

Breast cancer is the most common cancer among women in Sweden.

She contacts here local healthcare center and gets an appointment the next day with her family doctor.

She meets with the family doctor.

He makes the examination but can’t rule out that the lump is cancer.

He refers her for a consultation to the breast clinic at the local hospital.

Maria is told she will receive the time for the consultation in the mail.

Maria is worried and what to get the examination over with. She checks her mail every day for the appointment.

After ten days she has still not received her appointment letter. She calls to try to find out status.

After some searching the nurse on the phone finds her referral and promise it will be processed later today.

Four days later she receives the appointment letter.

The appointment is scheduled for the next week.

Today it’s time for the mammography and ultra sound.

Maria arrives a little bit early. She sits down in the waiting room.

15 minutes after the scheduled time her name is called

The mammogram and ultra sound just takes few minutes.

She is once again sent home as the referral to the breast surgeon is sent.

Ten days later she is due back at the breast surgeon at the local hospital.

The breast surgeon has analyzed the images but unfortunately he can’t rule out cancer. He need to refer her to a cytologist so they can take a tissue sample.

Maria is sent home and she is now out of herself of worry and can’t remember a thing the surgeon told her.

Would she be sent a new appointment or should she schedule one her self?

The next day she calls back to the hospital, but can’t get by the automatic machine. She leaves a message.

Later that same day she is called back by a nurse. She explains that a referral has been sent to the cytologist.

She is told that she has an appointment in two weeks.

Two weeks of constant worries Maria meets the cytologist. He takes a tissue sample.

He explains that the sample now needs to be analyzed and the result will be sent to the breast surgeon she meet earlier. The doctor don’t know exactly how long the analysis will take as the lab is usually very busy.

She will receive an appointment in the mail.

After six long weeks Maria is back at the breast surgeon for the diagnose.

Now let us meet Anna.

It is a gray Tuesday morning and when in the morning shower Anna discovered a lump in her breast.

At lunch she shares her worry about the lump with her best friend.

She tells Anna about the “On stop breast clinic” at the local hospital. Anna decides to check it out as soon as the lunch is over.

Back at her computer Anna finds the information on the “One-stop breast clinic”.

Next time it is open is in two days. She decides to go.

It is now Thursday afternoon and she walks into the clinic.

She immediately gets examined by a nurse. The lump definitely needs to be examined.

Anna is sent to the waiting room and will be called as soon as the doctor is available.

Only 15 minutes later a breast surgeon calls her name. He examines her breast. He can’t rule anything out.

He want to take a ultrasound and a mammogram.

Anna is one again sent back to the waiting room. You will be called as soon the nurse is available, she is told. She prepares herself for a long wait.

But just after a few minutes her name is called and a specially trained nurse take the mammogram and then a doctor performs the ultrasound. They confirm the lump in the breast. But a tissue sample is needed.

The nurse follows Anna to a cytologist who takes a tissue sample.

He apologues as he asks Anna to take seat in the waiting room again as the sample is sends off for analysis.

Anna is one again back in the waiting room. She buys a soft drink in the vending machine and starts reading a magazine.

A few minutes later, to her surprise, she is back to the breast surgeon and he gives her the diagnose.

Both Maria and Anna went through the same diagnose process steps but with two totally different experiences.

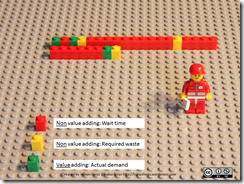

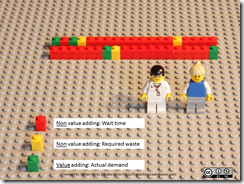

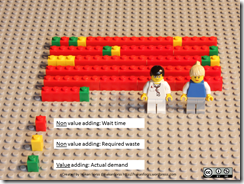

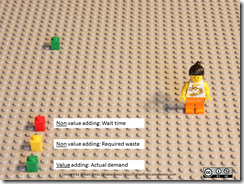

For Maria it took over 1000 hours to get her diagnose but it took less than 60 hours for Anna. How come they had such different experiences? Maria’s process time line is full of red LEGO bricks. Anna’s not so much. Why?

The two different process has been optimized based on two different business strategies.

|

|

| Maria’s process is optimized from the different healthcare units perspectives. It has been optimized for resource efficiency. This means that the process is optimized to keep the doctors, nurses and machines as busy as possible. This is supposed to drive down the cost per activity. The result is most often a process full of red and yellow bricks. | On the other hand, Anna’s process is optimized for flow efficiency. The process is also optimized on her as the customer. This means that the process is optimized to have Anna go through the process as fast as possible with as little wait time as possible, not so many red bricks. How busy the doctors, nurses and machines are is a secondary concern. |

You may think that the process Anna went through is much more expensive than the process Maria went through. But in fact the “One-stop shop” concept that focus on flow efficiency costs the same or less. This is often due to the fact that most yellow bricks, required waste, can be removed from the process.

If you would build a LEGO time line of your processes, would they be mostly red and yellow? Or would they be mostly green?

This story is my free translation and adaptation of a similar story in the great book This is Lean: Resolving the Efficiency Paradox by Niklas Modig and Pär Åhlström

This story is my free translation and adaptation of a similar story in the great book This is Lean: Resolving the Efficiency Paradox by Niklas Modig and Pär Åhlström

I highly recommend this book too anyone who wants to learn more about Lean.

For more info: http://www.vadarlean.se

The images in this post is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported License.

The images in this post is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported License.

Verkligen snyggt och enkelt visualiserat!

Hi Hakan

Great message and especially great visual display of the message, I really like it.

We rarely stop to think that a systems process if created from the wrong perspective is actually counter productive in the extreme. What you didn’t add is that the longer system can also lead to higher treatment cost because it delays the start of treatment needlessly. Many medical conditions are actually cheaper and easier to treat the sooner they are caught, yet we have designed most medical systems to needlessly delay treatment so that we can maximize the use of the facilty or the personel in the system, instead of building them to handle the patient the fastest and best way possible.

In Canada like is Sweden, to much of the healthcare system was designed to serve its facilties, equipment and staff, instead of the patient. It than not only adds needless handling and extra paper work, but delays treatment which also adds extra costs.

Hi Robert,

You are correct. I did not include the potential cost for treatments due to the long lead times until the correct diagnose is done.

I also left out Maria’s cost of going back and forth to the different clinics. I also left out the emotional agony for the patients. Can you imagine waiting as long as Maria did to get a life changing diagnose like that. How efficient is someone in Maria’s situation at work during the time she has to wait.

/ Håkan

fantastic visual and verbal comparisons

The problem with this article is, that is show the problem only from the customer perspective. It does not show wait time of the medical staff. Which is in fact waste time of the staff, because it costs money.

Even if you employ the flow system you hit the classic trade-off between waste time of the staff and wait time of the customers and you have to balance these (according to business rules, money, etc.).

Back to the example – so the art is to change the waste time – yellow bricks – into the staff wait time. So as the cost of the service is the same, but results in less hassle for the customer. I am afraid Anna would have much more wait time – red bricks, if she pays the same money of the service. Maybe Anna’s time could be half the Maria’s, but definitely it cannot be order of magnitude less.

It is a deliberate business strategy to focus on the customer’s perspective. This strategy of focusing on Flow Efficiency first and Resource Efficiency second is called Lean. Yes it is a trade-off curve. Organizations using the Lean business strategy will be on the Flow Efficiency side of this trade-off curve first and Resource Efficiency second. See Lean – a strategy on the path towards Nirvana.

By focusing on Flow Efficiency first you will shine a spotlight on the non-value adding steps in your process (red and yellow bricks) and you can start to remove them. By removing wait time (red bricks) in your processes you will gain one resource that can’t be bought by any money in the world – Time. By removing other non-value adding process steps (yellow bricks) you free people and resources to do value adding work and more process improvements.

It is counter intuitive to say the least, but Anna’s process in this example is actually less expensive to run than Maria´s. There are many examples of this out there, both in healthcare and in other industries.

/ Håkan

Yep, I know Lean process and I am a fan of agile in IT. I just want to say this article is good for lean enthusiasts to sight: “Aaah, the Lean is so nice!”. But it hardly change mind of any “resource efficiency” manager.

If the Anna’s process is less expensive, then prove it! (And you have a topic for your next article.)

Lean Thinking is counter intuitive to many. So no, if you don’t want to change no arguments in the world will change your mind.

Take a look at this article as an example of cost savings when using a focus on Flow Efficiency Denver Health saves millions using Toyota efficiency principles

Also take a look at Lean in British Columbia’s

Health Sector

Here are some more Lean Case Studies

/ Håkan

Awesome article. Thanks for sharing. I am developing a workshop on Lean thinking and value stream mapping, and I have been trying to think of some scenarios that many people from different work settings could relate to. This example is ideal. I hope you don’t mind that I use it?

I’m glad you like it Karen. The story is my free translation and adaptation of a similar story in the great book “Vad är Lean” by Niklas Modig and Pär Åhlström. You should really talk to them if you want to use this story. I will send you their contact information.

/ Håkan

Wonderful visualization, thanks!!

“The perfect hand off is no hand off” – quotation attributed to Steve Spear. “Zero hand off” is probably not possible in your scenario with various specialists involved, but I experienced it in a healthcare setting once when I broke my ankle and was taken through diagnostic radiology imaging with no handoff: from sign-in, through imaging, to being handed the phone to discuss results with my doctor, by ONE PERSON, who took me through the whole thing. The coffee I bought expecting a long wait was still hot as I hobbled back to the car! As someone applying lean in another industry, I was amazed!

Yes, Steve Spear is right. The perfect hand off is no hand off. Not easy to achieve but well worth striving for in most processes.

/ Håkan

This is a wonderful example for making a process lean and customer centered. It has happened in real life, at least according to the information in the book Switch: How to Change Things When Change Is Hard, by Chip Heath & Dan Heath , 2010.

Great visual example of Value Add vs. Non Value Add! The wait-time timelines are rather precise, even in a Canadian environment.

Thank you for this interesting article! What isn’t mentioned in the article is the impact of such situation on patient’s life: all these days when she can’t really focus on her work or her family because on the back of her head she still thinks about her health. It doesn’t really matter if it is about your health or about repairing your car – if it is unfinished it occupies your mind and makes you less productive, more depressed etc. Somehow it reminds me about GTD and closing all mental loops – you simply can’t close them because you do not control them.

You are very correct Tomek. If you take the pain and suffering into account as well then Marias situation is even worse. Flow Efficiency FTW!!